PSA(Pressure Swing Adsorption) for Making Oxygen-Double Eccentric Butterfly Valve Application

2016-11-05

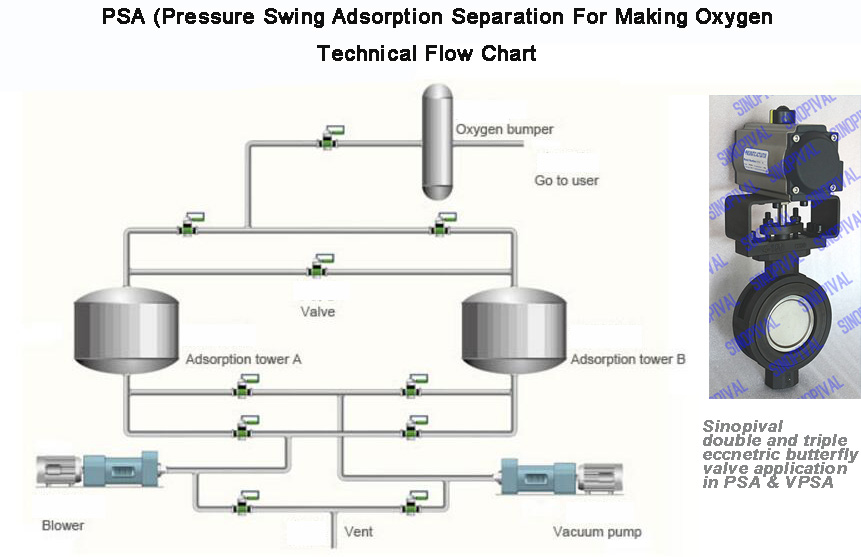

High performance butterfly valves,generally refers to double eccentric butterfly valve and triple eccentric butterfly valve,due to their excellent working performance and high sealing ability (compared with concentric butterfly valve) are widely used in petrochemical,power plants,metallurgy,civil heating fields.Eccentric butterfly valves have the good working performacne to meeting sever and strict requirements in many different industries.Today, we are going to introduce the application of eccentric butterfly valve in air separation for making oxygen,hydrogen,CO etc. At present,the mature air separation system is PSA(Pressure Swing Adsorption),it need certain number of programmed valves (valve parts usually double or triple eccentric butterfly valve) in its pipeline system to control and adjust the medium.

Sinopival double (and triple) eccentric butterfly valve are widely used in this kind of PSA system due to the valves’ excellent features:

1-Long service life,on-off 1 million times

2-Super reliable sealing performance:bidirectional sealing zero bubble

3-Patented seat design

4-Vacuum servie ability

5-Both liminated seat and full metal seat avaialble

6-Available fully rated to Class 2500lb

7-Anti-blowout device design

8-Fire-safe design optional

9-Excellent flow and throttling characteristics covering services from cryogenic to high temperature

Following we are going to briefly introduce application of double (and triple) eccentric butterfly valve in PSA (VPSA) process for making oxygen gas

PSA(Pressure Swing Adsorption for Making Oxygen) Introduction

1. The Main Technologies and Comparison of Air Separation & Oxygen Making

Oxygen in industrial production and daily life has a wide range of uses, the air contains 21% (volume concentration) of oxygen, is the cheapest oxygen raw materials, so oxygen is generally obtained by air separation.

1.1 Technologies of Air Separation & Oxygen Making

1.1.1 Cryogenic separation process: it’s the traditional oxygen making technology, the oxygen made in this way has high purity, wide product variety and suitable for large-scale oxygen making.

1.1.2 Pressure swing adsorption process (PSA): it’s new oxygen making technology, featured with low investment, low energy consumption, suitable for low purity request, small & medium scale applications.

1.1.3 Membrane separation process: not yet mature and this kind of technology are not applied in industry and come into use.

1.2 PSA process features (compared with membrane separation process)

1.2.1 The PSA process is more simple and does not require complex pretreatment equipment.

1.2.2 Oxygen purity can reach up to 95%, nitrogen content less than 1%, the rest is argon.

1.2.3 Oxygen making scale smaller than 10000m3 / h, the consumption of electricity is lower, smaller investment;

1.2.4 High degree of automatic operation of the device, convenient to open and stop;

1.2.5 The equipment operation independence is strong, the security is high;

1.2.6 The device is simple, flexible operation (part of the load is superior, conversion speed of the load is faster);

1.2.7 Low operating and maintenance costs;

1.2.8 Low cost of civil works, occupy less land.

1.3 Comparison Between Pressure Swing Adsorption Separation Process and Membrane Separation Process (refer to following table 1)

| Item | Membrane Separation Process | Pressure Swing Adsorption Separation Process |

|---|---|---|

Separation Principle |

Liquefied air, separate oxygen and nitrogen according to their different boiling point |

Raise pressure and adsorption,vacuum pumping and desorption,adopt the different adsorbability of oxygen and nitrogen to achieve separation |

| Main Characteristics of Equipment | Complex technology process,more facilities required,including air compression system, air precooling system, air purification system, the expansion unit, heat exchange system and rectification tower etc | Simple process, less equipment, including blower ,vacuum pump and the adsorption tower, etc |

| Process Characteristics | Operated at -160~-190℃ cryogenic environment | Normal temperature operating |

| Operation Characteristics | Long start time, usually in 15 to 40 hours, must continuously operate, can not be intermittent operation,if a short shutdown, restart require long time. | Short start time,generally less than 30 min.,both works for continuous and intermittent running |

| Maintenance Characteristics | Complex facilities structure,high machining precision,big technical difficulty of maintenance,and high maintenance cost | Sinple facilities structure, small technical difficulty of maintenance,and low maintenance cost |

| Civil Works and Installation Characteristics | Occupy large land area, high requirement for factories and infrastructure, high project cost.Long installation cycle, big technical diffculty, high installation costs. | Occupy small land area, no special requirement for factories and infrastructure,low project cost.Short installation cycle, low installation costs |

| Oxygen-Making Cost | High electricity consumption for small& medium scale oxygen making,about 0.5~1.0KW/Nm3 | Low electricity consumption,about0.32~0.35KW/Nm3 |

| Safety | The equipment is regulated by the pressure vessel specification. Can cause local accumulation of hydrocarbons, there is the possibility of an explosion. | Low operating pressure, free from pressure vessel regulations, does not cause local accumulation of hydrocarbons |

2. Principle of Pressure Swing Adsorption Separation for Making Oxygen

2.1 Principle of pressure swing adsorption separation for making oxygen

The main components in the air are nitrogen and oxygen. By selecting the adsorbents that have different adsorption selectivities to nitrogen and oxygen, an appropriate process is designed to separate oxygen from nitrogen and obtain oxygen.

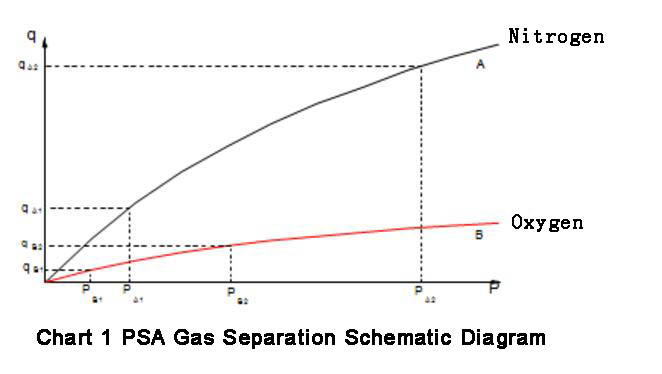

Nitrogen and oxygen both have a quadrupole moment, but the quadrupole moment(0.31A \u65289X) of nitrogen is much larger than that (0.10 A\65289X)of oxygen, so the adsorption capacity of nitrogen on zeolite molecular sieve is stronger than that of oxygen (stronger acting force between nitrogen and molecular sieve surface, as shown in Chart 1 below).

Thus, under pressure status when the air is passing through the adsorbent bed containing the zeolite molecular sieve adsorbent, the nitrogen is adsorbed by the molecular sieve, while the oxygen is less adsorbed and enriched in the gas phase and flows out of the adsorbent bed to separate the oxygen gas and the nitrogen gas to obtain oxygen gas . When the molecular sieve adsorbs nitrogen to near saturation, shut down air flow and reduce the pressure of the adsorbent bed. The nitrogen adsorbed by the molecular sieve can be desorbed and the molecular sieve regenerated and reused. Two or more adsorbent beds to switch jobs, can continuously produce oxygen.

Argon and oxygen have close boiling point, the two are difficult to separate, them together in the gas phase to be enriched. Therefore, the pressure swing adsorption oxygen plant usually can only get 90% ~ 95% concentration of oxygen (oxygen up limit of 95.6%, the rest is the argon), compared with concentration of 99.5% obtained from membrane air separation unit , also called oxygen-rich.

2.2 Brief Facilities Introduction for Pressure Swing Adsorption Separation for Making Oxygen

From the above principle, it can be seen that the adsorbent bed of pressure swing adsorption air separation oxygen plant must contain at least two operation steps: adsorption and desorption. Thus, when there is only one adsorbent bed, the product oxygen is interrupted. In order to continuously obtain the product gas, usually two or more adsorbent beds are provided in the oxygen plant, and additional necessary steps are provided in view of energy saving and smooth operation.

Each adsorbent bed is typically subjected to repetitive steps of adsorption, forward depressurization, evacuation or depressurization regeneration, rinse displacement, and pressure equalization. At the same time, each adsorbent bed is in different operating steps, under the control of the computer time switch, so that several adsorption bed in coordination, at the pace of time are staggered, so that the pressure swing adsorption device can run smoothly, continuous obtain product gas.

According to the different methods of desorption, pressure swing adsorption oxygen is divided into two processes (see table 2 above):

2.2.1 PSA process: under pressure adsorption (0.2 ~ 0.6MPa), atmospheric pressure desorption. Investment is small, simple equipment, but high energy consumption, suitable for small-scale oxygen-making applications.

2.2.2 VPSA process: atmospheric pressure or slightly higher than atmospheric pressure (0 ~ 50KPa) under the adsorption, vacuum desorption. Equipment is relatively complex, but the higher efficiency, lower energy consumption, suitable for large-scale occasions of oxygen-making.

Table 2 Comparison Between PSA and VPSA process

| Technology Process | Suitable for Oxygen-making Sclae m3/h |

Adsorption Pressure KPa |

Desorption Pressure Kpa |

Concentration of Oxygen % |

Electricity Consumption KWh/m3 | Oxygen Rate % |

|---|---|---|---|---|---|---|

| PSA | ≤200 | 200~600 | atmosphere | 80~93 | 0.7~2 | 30~45 |

| VPSA | 100~10000 | 0~50 | -45~-80 | 80~95 | 0.3~0.5 | 46~68 |

For the actual separation process, other trace components in the air must also be taken into account. The adsorption capacity of carbon dioxide and water on conventional adsorbents is generally much greater than that of nitrogen and oxygen, and the adsorbent can be adsorbed and removed by the addition of a suitable adsorbent (or by the oxygen-making adsorbent itself). The number of adsorption towers required for the oxygen plant depends on the scale of the oxygen generation, the adsorbent performance and the process design, and the running stability of the multi-tower operation is relatively better, but the equipment investment is higher. The current trend is to using highly efficient oxygen adsorbents ,minimize the number of adsorption towers as less as possible, employing short operating cycles to improve plant efficiency and to save investment .